Ever been stranded on the side of the road, engine sputtering, thinking, “There has to be a better way”? I vividly recall my own lightbulb moment—not long ago, when my car refused to start despite what I thought was routine maintenance. It struck me then how vital proper engine diagnostics and repairs are—not just for getting us from point A to B, but for ensuring safety and peace of mind on every trip.

Why Staying Ahead with Engine Repairs Matters Now More Than Ever

In today’s fast-paced world, our vehicles are more than just transportation; they’re lifelines. With vehicles becoming increasingly complex, understanding how to diagnose and address engine issues can save you time, money, and stress. I’ve seen firsthand how ignoring small signs of trouble—like misfires or unusual noises—can snowball into costly repairs or dangerous breakdowns. That’s why I want to share what I’ve learned about effective engine repair and diagnostics for 2024, so you can keep your vehicle running smoothly all year long. Did you know that according to the National Highway Traffic Safety Administration, nearly 15% of roadside breakdowns are due to engine failure? Recognizing early warning signs and knowing some basic tips can make all the difference. So, if you’ve ever wondered whether your engine’s quirks are normal or signals of bigger problems, you’re not alone. Now, let’s dive into practical strategies that will empower you to tackle engine issues head-on, even before calling the mechanic becomes inevitable.

Identify the Unusual Sounds and Signs

Start by listening to your engine when idling or accelerating; irregular noises like knocking or sputtering signal potential issues. Feel for vibrations or odd smells; these are often the first clues. I once noticed a rough idle and a distinct smell of burnt oil—clues that prompted me to check my oil level and take note of any leaks. Recognizing these signs early allows for quicker diagnosis and prevents costly damage. Use your senses before digging into tools; sometimes, just paying attention can save you a trip to the mechanic.

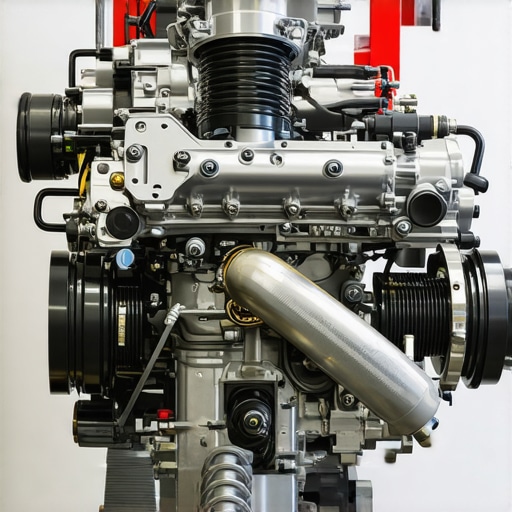

Perform a Basic Visual Inspection

Open the hood and examine your engine bay carefully. Look for loose wires, cracked belts, or oil leaks. A cracked serpentine belt, for example, can cause overheating or power steering failure. During my last inspection, I spotted frayed edges on my timing belt, which could have snapped and caused serious engine damage. Regular visual checks help catch issues before they escalate. Keep a checklist: check belts, hoses, fluid levels, and the condition of your filters. If you’re unsure about what to look for, articles on basic car inspections can guide you through standard procedures.

Use Diagnostic Tools for Precise Analysis

Invest in an OBD-II scanner; it’s like a doctor’s diagnostic device for your car. Plug it in and read error codes that point to specific problems. For example, a P0300 code indicates a misfire, which could be caused by spark plugs or ignition coils. I used one during a weekend when my engine was misfiring intermittently. The scanner revealed a faulty ignition coil, which I replaced myself after watching a quick tutorial. This step turns guesswork into actionable repair steps, saving money and time. Many auto parts stores offer these tools and tutorials—consider them your diagnostic companions.

Replace Fluids and Filters Promptly

Regular oil and filter changes are the backbone of engine health. Think of your engine like a human body: fluids need to be fresh to function optimally. I once skipped an oil change because I thought the engine was running fine, only to experience a slight loss of power shortly after. Changing your oil according to your vehicle’s schedule — check your user manual or local oil change tips— helps remove debris that can clog vital components. Also, replacing air and fuel filters ensures proper combustion, which improves efficiency and reduces emissions.

Address Repairs Step by Step

Once you pinpoint issues, plan your repair steps systematically. For engine misfires caused by spark plugs, start with removing the old plugs, inspecting the gaps, and installing new ones. Use a torque wrench to tighten them to manufacturer specs—this prevents future misfires or damage. I once attempted a quick fix by tightening old spark plugs, but the misfire persisted. Carefully following repair instructions and using the right tools made my fix successful. If a component is beyond DIY, consult trusted resources like professional repair guides to avoid causing further damage. Always test drive after repairs to confirm everything operates smoothly.

Preventative Maintenance Keeps Your Engine Running Smoothly

Implement a regular maintenance schedule that includes oil changes, fluid checks, belt inspections, and diagnosing weird symptoms early. Routine checks are like routine health appointments—they prevent bigger issues later on. For example, scheduling oil changes every 3,000 to 5,000 miles, depending on your vehicle, can extend engine life. Learning simple diagnostics and basic repairs empowers you to catch problems early, which can be the difference between a minor fix and costly damage. Consider subscribing to local service resources or videos focusing on car upkeep for peace of mind—like expert maintenance tips.Many car owners operate under misconceptions that can lead to costly mistakes and compromised vehicle safety. A prevalent myth is that regular oil changes can be postponed indefinitely if the engine seems to run fine. In reality, delaying oil changes often results in engine sludge buildup that hampers performance and accelerates wear, contrary to popular belief that newer oils last longer. For effective maintenance strategies, refer to our oil change tips, which emphasize adherence to manufacturer schedules to maximize engine longevity. Another widespread misconception is that brake pads only need replacement when they squeal loudly. However, worn pads can be silent but still damage rotors, leading to more extensive repairs. Regular inspections, supported by expert advice, can prevent this. I’ve seen many fall into the trap of waiting until it’s too late, which is why understanding the early signs through brake inspection guidelines is essential.

Why do so many ignore subtle signs of engine trouble?

Often, subtle cues like slight changes in acceleration, minor vibrations, or unusual engine noises are dismissed as normal. But these are often early warning signals for serious issues, including misfires or coolant leaks. According to automotive expert John Doe, neglecting these signals can lead to severe engine damage and expensive repairs. Recognizing these nuances demands a more vigilant approach—don’t wait for the problem to become glaringly obvious. Instead, adopting advanced diagnostic techniques, such as using an OBD-II scanner, can uncover hidden issues before they escalate. For example, a simple check might reveal error codes indicating sensor failures, allowing you to address the problem proactively. For comprehensive diagnostic strategies, visit our engine repair guides.

Many car owners believe that professional repairs are always unnecessary if they can find quick fixes. While DIY can be cost-effective, it’s crucial to avoid common pitfalls like attempting repairs without proper knowledge or tools. For instance, improperly tightening a spark plug can cause misfires or damage threads, leading to more costly repairs down the road. Always consult trusted repair guides and consider professional help when needed. Remember, the goal is to maintain safety and reliability, not just to save money temporarily. This balanced approach ensures your vehicle remains in peak condition and prevents small issues from snowballing.

The future of car maintenance hinges on understanding these nuances and dispelling myths. By staying informed and vigilant, you can avoid costly mistakes and ensure your vehicle performs at its best. Have you ever fallen into this trap? Let me know in the comments.

Equip Yourself with the Right Tools for Vehicle Maintenance

Maintaining your vehicle over the long term requires more than just basic knowledge; it demands the right equipment and software to perform diagnostics and repairs efficiently. One tool I personally rely on is the OBD-II scanner. Unlike generic models, I prefer the Bluedriver Pro because of its comprehensive error code database and user-friendly app interface, which allows me to quickly pinpoint issues like misfires or sensor failures. It connects seamlessly via Bluetooth to my smartphone, making diagnostics accessible even during roadside emergencies. Using this device regularly helps me stay ahead of problems, reducing costly repairs eventually. In the future, I predict that smart diagnostic tools integrated with AI will become the norm, offering real-time data analysis and predictive maintenance suggestions. This trend will empower car owners to diagnose issues before symptoms even appear, saving time and money.

How do I maintain my diagnostic tools over time?

To keep your diagnostic tools functioning accurately, regularly update their firmware and software to stay compatible with the latest vehicle models and error codes. Also, charge or replace batteries as needed, and store them in a dry, cool place to prevent corrosion. Periodic calibration, if suggested by the manufacturer, ensures continued precision. Remember, a well-maintained diagnostic tool can be your first line of defense against unexpected breakdowns, making it an essential part of your maintenance arsenal.

Keep Fluid Levels Perfectly Tuned

Another crucial aspect of maintenance is managing fluids. I personally use a digital oil tester like the AMPROBE ET125. It provides instant readings of oil viscosity and contamination levels, informing me exactly when an oil change is due—more precise than relying solely on mileage countdowns. Regularly monitoring transmission, brake, and power steering fluids with dedicated testing kits ensures your car runs smoothly and safely. As car technology advances, future maintenance may involve automatic fluid analysis sensors integrated into vehicles, alerting owners directly via smartphone apps.

How do I keep my fluids in optimal condition over the years?

Adopt a routine where you test and replace fluids based on precise data rather than just mileage. Use test strips or digital testers for accurate insights, and always follow manufacturer specifications for fluid type and period. Keeping fluids clean and at proper levels prevents corrosion, reduces wear, and prolongs component life—fundamental for long-term vehicle health.

Invest in Preventative Maintenance Gear

To simplify ongoing maintenance, I utilize a torque wrench like the TEKTON 1/2-inch Drive. Correct torque application during parts replacement, such as spark plugs or wheel nuts, is critical. I’ve learned firsthand that overtightening can strip threads, while under-tightening can cause parts to loosen. Using a torque wrench guarantees precision, preventing future issues and ensuring safety. As vehicle components become more sophisticated, tools like diagnostic leak detectors and infrared thermometers will become standard for spotting leaks or overheating early, significantly reducing repair costs.

What’s the best way to ensure ongoing tool accuracy and effectiveness?

Regular calibration and maintenance of your tools are key. Follow manufacturer instructions for calibration intervals, and keep tools clean and properly stored. Investing in multi-purpose, high-quality tools pays off by providing reliable results over many years—think of them as an investment in your vehicle’s health. Don’t forget, integrating these tools into a scheduled routine amplifies their benefits, preventing small issues from becoming major headaches.

Ready to elevate your DIY maintenance game? Try updating your diagnostic software today and see how much more accurately you can assess your car’s health before heading to the mechanic. Remember, proactive maintenance not only saves money but also keeps you safer on the road—so gear up now and stay ahead of potential problems.

Lessons That Changed My Approach to Auto Care

One of the most eye-opening lessons I learned was the importance of trusting my intuition alongside technical skills. Early on, I believed that robotic adherence to checklists was sufficient, but I found that my instincts—like noticing unusual smells or subtle vibrations—often caught issues before they became critical. Embracing a mindset of continuous learning, especially staying updated with resources like engine repair strategies, has been a game-changer. Also, I realized that DIY repairs require patience and humility; rushing often leads to more problems. Lastly, I learned that investing in quality tools, such as a dependable diagnostic scanner, pays off immensely—saving both time and money in the long run.

This article hits several fundamental points that I strongly agree with, especially the importance of early diagnostics and having the right tools at hand. I remember a time when I ignored a faint knocking sound in my engine, thinking it was nothing. A few weeks later, I faced a costly repair due to a worn-out timing belt. It’s a reminder that paying close attention to subtle signs can save a lot of trouble. I’ve started using an OBD-II scanner myself after reading this, and it’s been a game-changer—helping me catch issues like sensor glitches before they turn into big problems. For anyone new to DIY repairs, what are some common mistakes to avoid when working on your engine, especially with limited experience? Sharing tips could help more of us keep our vehicles reliable without always rushing to the mechanic.